Competitive Titanium Analysis

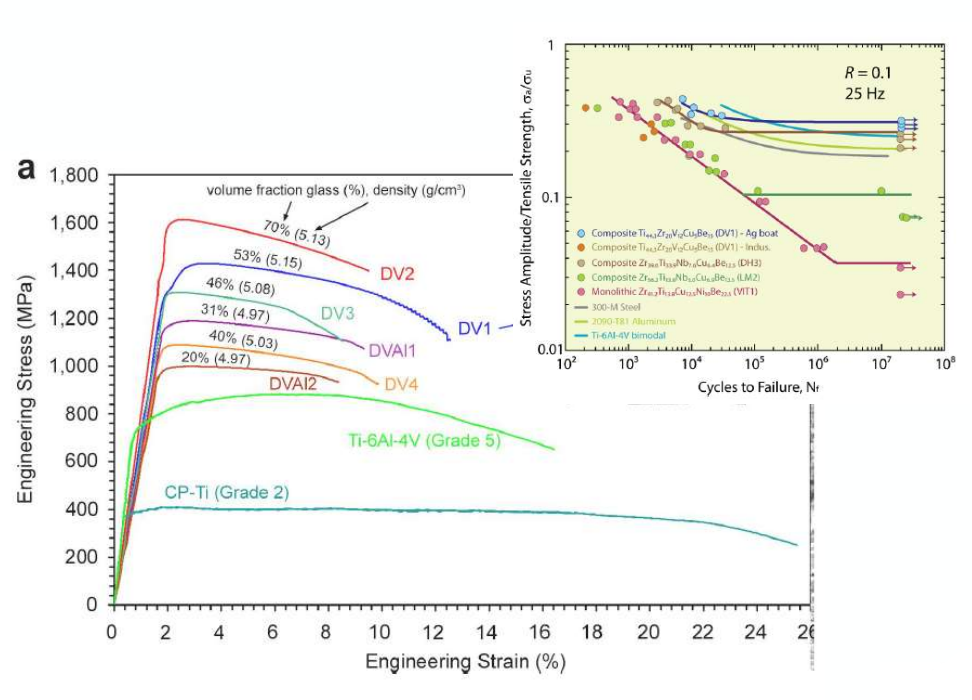

Shown below are two of the most common titanium alloys used in various industries: commercially pure titanium and Ti64. As shown in Fig. 1, bulk metallic glasses (denoted by DV-) massively outperformed Ti64 and Cp-Ti in terms of yield strength and ultimate tensile strength [1]. Although a loss of ductility was observed in the BMGs, this can be attributed to the increase in strength which would fare much better than Ti64/Cp-Ti in cyclic loading conditions. Another advantage our alloy and BMGs possess over more traditional alloys is the ability to be die-casted. Machining Ti-based alloys is somewhat costly whereas BMGs do not have this disadvantage. Since BMGs have a much lower solidus temperature [1], they are easily able to be cast into molds of net shapes.

[1] Hofmann, D. C., Suh, J.-Y., & Johnson, W. L. (2008, December 23). Development of tough, low-density titanium-based bulk metallic … – PNAS. PNAS. Retrieved May 10, 2022, from https://www.pnas.org/doi/10.1073/pnas.0809000106

Market Strategy

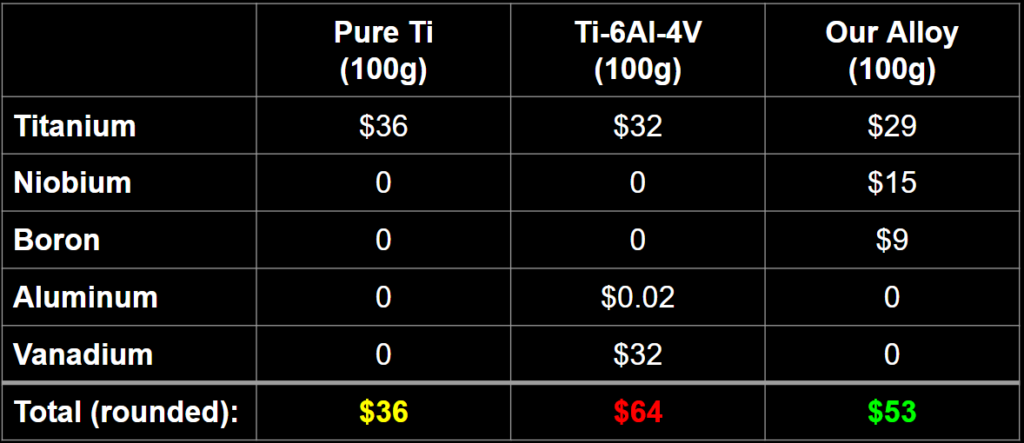

Initial prototyping of our samples were done in 150 g batches. There were many iterations of what we now denote as “Our Alloy” but the prices shown reflect the highest performing sample. To simplify calculations and to ensure a more direct comparison, 100 g samples were calculated. We assume that this nearly 20% reduction in price would be beneficial for commercial use when the viability of our product has been confirmed.

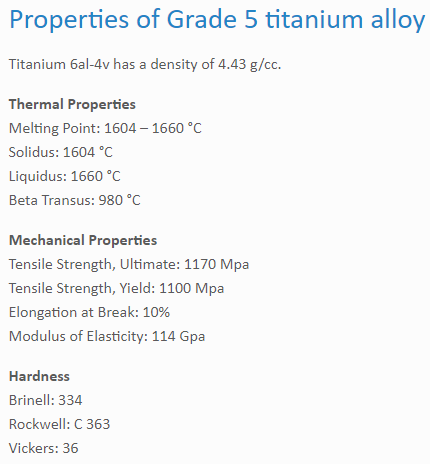

In addition to the financial advantage, the applications for our material have been highly considered as well. The first market we plan on trying to break into would be the biomedical industry, specifically spinal implants. Currently, implants are made of the Grade 5 TI6AL4V alloy as analyzed above, but Grade 23 Ti6AL4V ELI alloy is also employed as well. Our new alloy improves on, and if not, maintains the mechanical properties of these alloys while at the same time providing other benefits such as ease of manufacturing and machinability.

Implant prices have been reported to be in the range of $400 to $1843 for a single pedicle screw, $540 to $2388 for an anterior cervical plate, and $938 to $7200 for a transforaminal lumbar interbody fusion cage [2]. We hope to alleviate those high price points while also maintaining the highest quality required for these items.

[2] Blackburn CW, Association of Cost Savings and Surgical Quality With Single-Vendor Procurement for Spinal Implants. JAMA Netw Open. 2019;2(11):e1915567. doi:10.1001/jamanetworkopen.2019.15567