Ti-Based Composites

A novel material for additive manufacturing

Titanium has one of the highest strength to density ratios of any metal, but has low ductility making it hard to utilize in additive manufacturing. Our product, a novel Titanium-based metal matrix composite (MMC), benefits multiple industries by outperforming current materials used.

One of the most attractive properties titanium possesses is its inertness within the human body; it does not disrupt human body processes. A majority of medical implants created today are made of Ti64, a material that has posed a hinderance when trying to be used in additive manufacturing. Other industries such as the aerospace or automotive industries struggle with similar problems. Our product touts this manufacturability while providing similar, if not improved properties in comparison to that and other commonly used materials for a cheaper price.

Titanium

The bulk material

Niobium

The β-phase stabilizer

Boron

The eutectic encourager

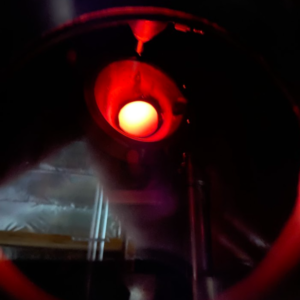

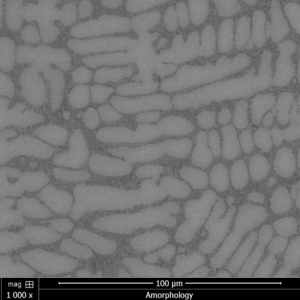

As stated before, our product is a MMC that utilizes a novel concentration of Titanium, Niobium, and Boron. The inclusion of Nb and B to a Ti metal encourages a glassy eutectic phase to form, increasing the strength of the material while also maintaining its ductility. This MMC is created with the help of an arc melting furnace. The raw elements are blasted with temperatures upwards of 1200° C, then cast into buttons and rods to be tested. Once verified, the material is further processed to be compatible with other additive manufacturing techniques.

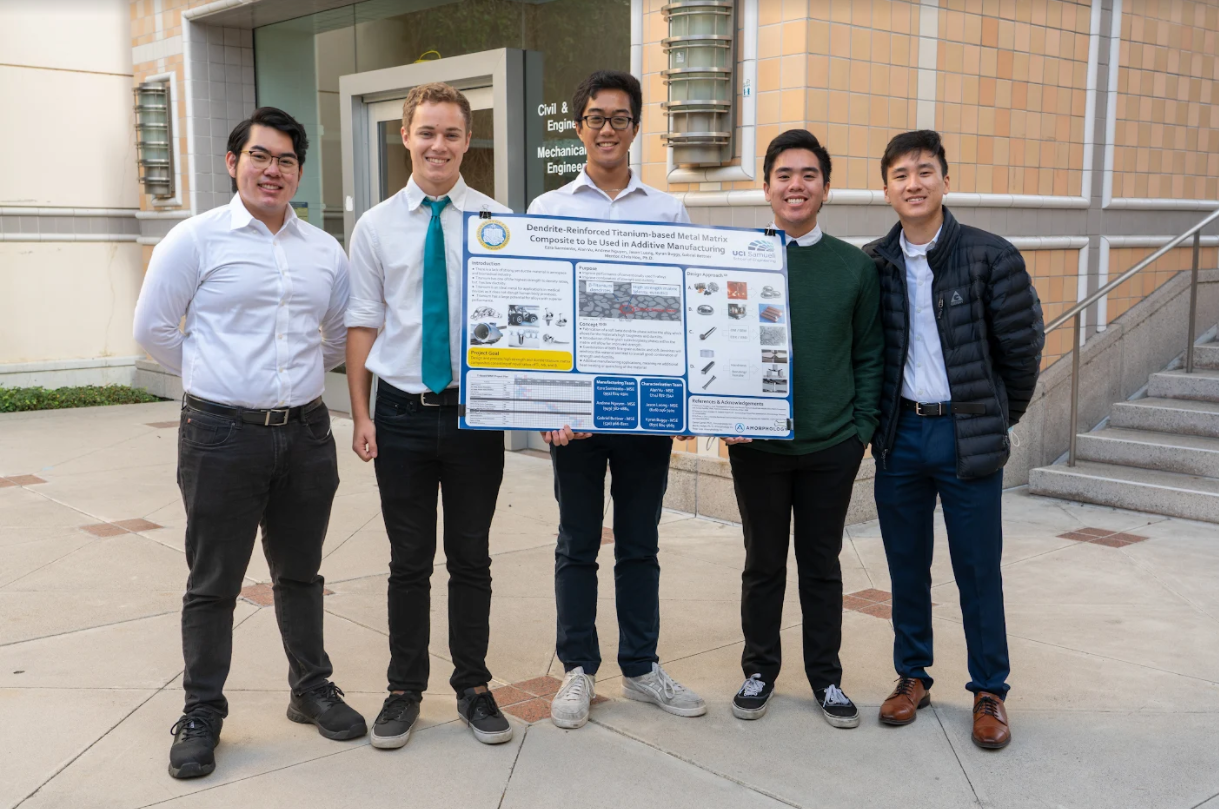

Meet the Team

Ezra Sarmiento – Team Lead

Materials Science and Engineering

Andrew Nguyen – Manufacturing

Materials Science and Engineering

Gabriel Bettner – Testing

Materials Science and Engineering

Jason Luong – Characterization

Materials Science and Engineering

Alan Vu – Characterization

Materials Science and Engineering

Kyran Buggy – Testing

Materials Science and Engineering and Applied Physics